Here's a breakdown of what it is and how it functions:

1. Definition and Purpose:

• A wet alarm check valve is a type of valve used in a wet pipe sprinkler system, which is a fire suppression system that keeps water constantly in the pipes.

• Its main purpose is to prevent backflow from the sprinkler system into the main water supply and to activate an alarm when water starts flowing due to a sprinkler activation during a fire.

2. How It Works:

• Under normal conditions, the water pressure on both sides of the valve (supply and system) is equal, and the valve remains closed.

• When a fire causes a sprinkler to activate, water flows out of the system, reducing pressure in the sprinkler pipes.

• This pressure differential causes the check valve to open, allowing water to flow into the system from the main supply.

• As the valve opens, it triggers an Alarm Mechanism (often connected to a mechanical gong or electronic signal), indicating that the system is discharging water and a fire event is occurring.

3. Components:

• Clapper: A movable part that opens and closes to control water flow.

• Trim piping and alarm devices: Connect to a water motor gong or an alarm pressure switch to signal an alarm.

• Drain connection: To remove excess water from the system during testing or maintenance.

4. Applications:

• Used in buildings where temperatures are consistently maintained above freezing to ensure water in the pipes doesn’t freeze.

• Commonly found in commercial, industrial, and residential buildings as part of their fire safety systems.

In summary, a wet alarm check valve is essential for ensuring the effective operation of a wet sprinkler system, maintaining water supply integrity, and triggering an alarm during fire events.

Certainly! The performance of a Wet Pipe Sprinkler System depends on the coordinated functioning of all its components. Each part contributes to how effectively the system detects, responds to, and mitigates fire hazards. Here's an overview of the main components and their contributions:

1. Pipes and Fittings:

• Role: The pipes act as the conduits that carry water from the main water supply to the sprinkler heads.

• Performance Impact: The pipes must be durable and properly installed to maintain consistent water pressure and flow. Proper sizing and layout ensure even distribution throughout the system.

2. Sprinkler Heads:

• Role: These are the points of discharge where water is released when a fire is detected. Each sprinkler head has a heat-sensitive element (e.g., glass bulb or fusible link) that activates when exposed to high temperatures.

• Performance Impact: The type and placement of sprinkler heads influence the coverage and effectiveness of fire suppression. Quick-response heads provide faster activation, improving the speed at which a fire is controlled.

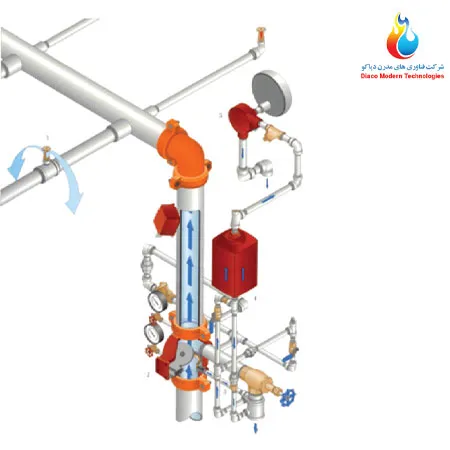

3. Wet Alarm Check Valve:

• Role: This valve maintains water in the pipes under pressure and opens to allow water flow when a sprinkler is activated. It also prevents backflow and triggers an alarm when it opens.

• Performance Impact: The valve's reliability affects how quickly water is released into the system. The alarm function provides immediate notification, ensuring that emergency response teams or monitoring services are alerted quickly.

4. Alarm System:

• Role: Mechanical or electronic components connected to the check valve (e.g., water motor gong, alarm pressure switch) generate an audible or electronic alarm when water flows due to sprinkler activation.

• Performance Impact: This component is critical for alerting building occupants and emergency services. Effective alarms reduce response time, increasing safety and minimizing fire damage.

5. Water Supply:

• Role: The source of water (municipal supply, fire pump, or water storage tank) must be reliable and maintain adequate pressure and volume for the system to function.

• Performance Impact: The capacity and pressure of the water supply determine the system's ability to sustain a continuous flow during a fire. Fire pumps, if used, boost pressure to ensure consistent performance.

6. System Monitoring and Control Panel:

• Role: The control panel receives signals from the alarm system and may notify monitoring services or building management automatically.

• Performance Impact: This ensures that the response is not solely dependent on people hearing the alarm. It adds a layer of reliability through automatic communication with emergency response services.

7. Pressure Gauges and Drains:

• Role: Pressure gauges monitor the system’s pressure levels, while drains help with maintenance and system testing.

• Performance Impact: These components ensure the system operates within its designed parameters. Regular maintenance using drains and pressure monitoring helps identify potential issues before a fire event.

Overall System Performance:

The performance of a wet pipe sprinkler system depends on how effectively these components work together. Key performance indicators include:

• Activation Time: How quickly the sprinkler heads detect and respond to heat.

• Water Flow and Pressure: The ability of the system to maintain adequate flow and pressure.

• Alarm Response: The immediacy and reliability of the alarm signal.

• System Integrity: Ensured by regular testing, maintenance, and adherence to codes and standards.

The system's design must be tailored to the specific building layout, occupancy type, and potential fire risks. When each component functions as intended, the system can quickly suppress or control fires, minimizing damage and enhancing safety for occupants.

A wet pipe sprinkler system is designed to automatically respond to fire by discharging water from sprinkler heads. It is a network of pipes filled with water under pressure that is activated when a fire triggers one or more sprinkler heads. The system works seamlessly to control or extinguish fires in their early stages.

Complete List of Equipment and Components:

1. Pipes and Fittings:

• Description: A network of pipes that run throughout the building to distribute water to sprinkler heads.

• Material: Usually made of steel, copper, or CPVC for corrosion resistance and durability.

2. Sprinkler:

• Types:

-Pendant: Hangs down from the ceiling, commonly used in most buildings.

-Upright: Points upward and is used in open-ceiling spaces.

-Sidewall: Mounted on walls for narrow spaces.

• Activation Mechanism: Heat-sensitive elements like glass bulbs or fusible links that break or melt at a set temperature, triggering water flow.

• Coverage: Different sprinkler heads offer varied spray patterns to cover specific areas effectively.

3. Wet Alarm Check Valve:

• Function: A valve that prevents backflow and holds water under pressure until activated by a drop in pressure (caused by a sprinkler head discharging).

• Associated Components:

-Retard Chamber: Slows down the activation of the alarm to prevent false signals due to transient pressure changes.

-Clapper Assembly: Allows water flow when pressure drops.

4. Alarm Devices:

• Water Motor Gong: A mechanical device that rings when water flows, creating an audible alarm.

• Alarm Pressure Switch: An electrical device that signals an alarm panel or monitoring system when water starts to flow.

5. Control Valves:

• Main Control Valve: Used to turn the water supply on or off to the system.

• Post Indicator Valve (PIV): A type of control valve with an indicator that shows whether the valve is open or closed.

6. Water Supply:

• Sources: Municipal water supply, fire pumps, or water storage tanks.

• Fire Pump: Used to boost water pressure when the municipal supply is insufficient.

• Jockey Pump: Maintains pressure in the system during non-fire conditions to prevent false activations.

7. Monitoring and Control Panel:

• Role: Receives signals from alarm devices and may notify a monitoring service or building management system.

• Functionality: Can activate other fire protection measures and alert emergency services.

8. Pressure Gauges:

• Location: Placed at key points, such as near the wet alarm check valve and main control valve, to monitor system pressure.

• Purpose: Ensure the system operates within designated pressure parameters for readiness.

9. Flow Switches:

• Purpose: Detects water movement in the pipes and triggers an alarm, confirming water discharge.

• Location: Installed downstream of the wet alarm check valve.

10. Drains and Test Valves:

• Main Drain Valve: Used to release water for maintenance and testing purposes.

• Inspector’s Test Valve: Simulates the activation of a sprinkler head to test system performance.

11. Backflow Preventer:

• Function: Prevents contaminated water from flowing back into the main water supply, ensuring safety and code compliance.

• Location: Installed at the main water supply connection.

12. Retard Chamber (optional):

• Function: Prevents false alarms by temporarily collecting excess water pressure before triggering the alarm.

How These Components Work Together:

• Normal Operation: The system remains pressurized with water, ready to discharge at any moment.

• Fire Activation: Heat from the fire causes the nearest sprinkler head to open, releasing water. This reduces pressure in the system, causing the wet alarm check valve to open and allow more water to flow.

• Alarm Triggering: The flow of water activates the connected alarm devices, alerting occupants and emergency response teams.

• Fire Suppression: Water continues to discharge until the fire is extinguished or manually stopped by closing the control valve.